Indium bromide (InBr3)

CAS number: 13465-09-3

Indium bromide (InBr3) is a chemical compound composed of indium and bromine. It's a white, crystalline powder that is also known as indium(III) bromide or indium tribromide. InBr3 is a Lewis acid, meaning it can accept an electron pair, and it finds use in organic synthesis and as a catalyst.

Related images

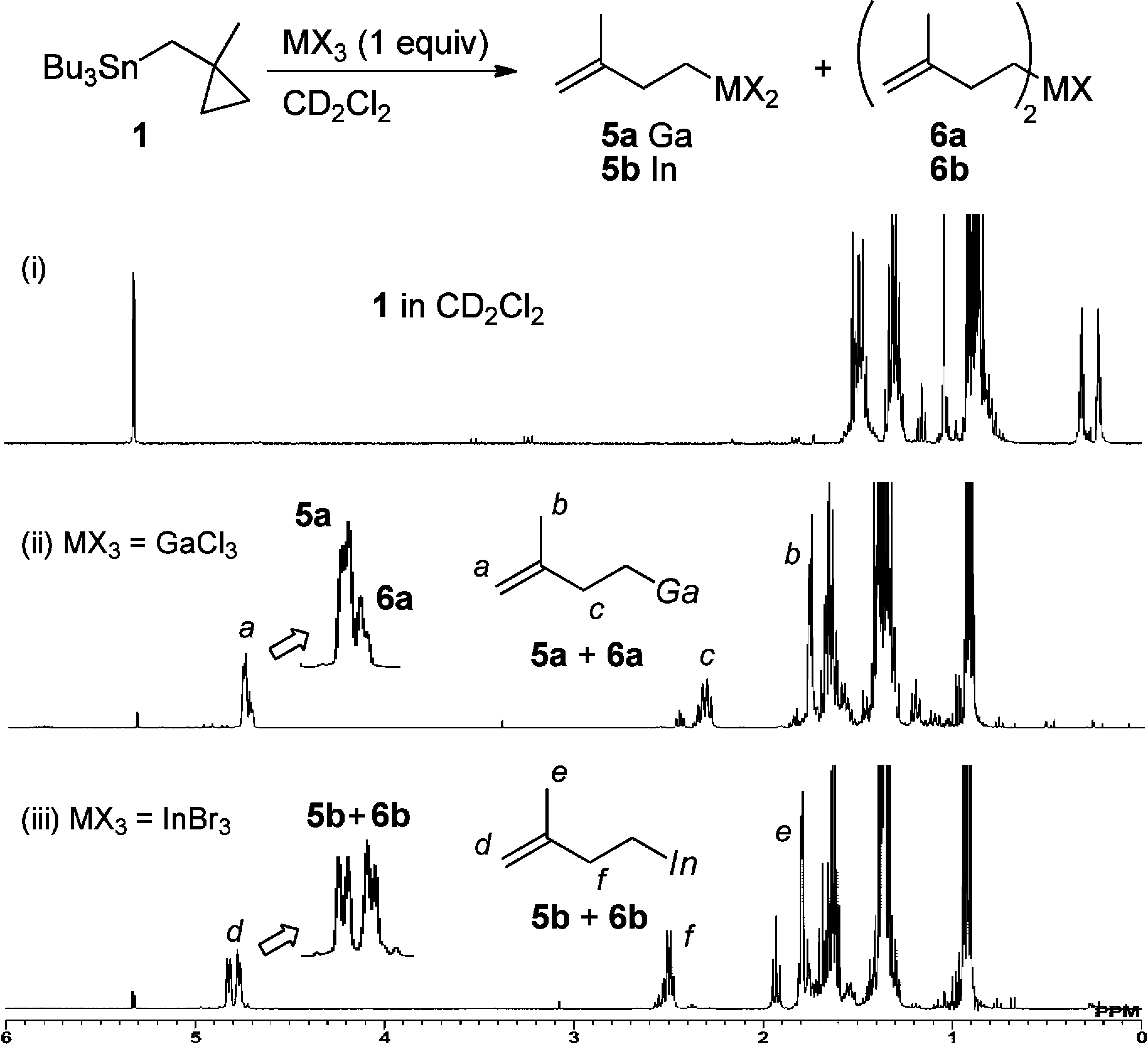

1H NMR spectra of (i) 1, (ii) the mixture of GaCl3 and 1, and (iii) the mixture of InBr3 and 1 in CD2Cl2.

Related Questions and Answers

A: The changes in gallium profile and sodium content after InBr3 recrystallization have significant implications for device performance. The decrease in gallium concentration at the surface and throughout the film depth, as observed by SIMS, could negatively impact device performance since a Ga-rich layer is typically desired at the front of the device to enhance open-circuit voltage. However, the increase in sodium content, which is generally beneficial for CIGS solar cells, could counterbalance some of these negative effects. The enhanced sodium concentration is associated with improved device characteristics, such as higher open-circuit voltage. Therefore, better control of the recrystallization process, such as adjusting the temperature or the amount of InBr3, is necessary to optimize the gallium and sodium profiles for high-efficiency device fabrication.

A: Recrystallization with indium bromide (InBr3) leads to notable changes in the elemental composition of CIGS films. X-ray fluorescence (XRF) and X-ray diffraction (XRD) analyses show a decrease in the Ga/III ratio from 0.24 to 0.05 and an increase in the indium content, making the films more copper-poor. This suggests that indium is added to the films during the InBr3 vapor treatment. Additionally, secondary ion mass spectrometry (SIMS) reveals a significant decrease in gallium concentration at the surface and throughout the film depth, accompanied by an increase in oxygen content, likely due to the hygroscopic nature of InBr3.

A: Post-deposition recrystallization with indium bromide (InBr3) at 400°C and 500°C significantly enhances the structural and electrical properties of CIGS thin films. The treatment leads to larger grain sizes and higher electrical conductivity. For instance, the grain size increases, as evidenced by the decrease in the full width at half maximum (FWHM) of the XRD peaks, and the electrical conductivity improves from 1.9×10⁻³ ohm⁻¹·cm⁻¹ for as-deposited films to 35.7×10⁻³ ohm⁻¹·cm⁻¹ for films annealed at 400°C with InBr3. Additionally, the carrier concentration and mobility also increase, contributing to the improved conductivity.